Aquaculture online monitoring solution

※ Background

China is one of the countries with the longest history of aquaculture in the world, with rich experience in aquaculture and popularization of aquaculture technology. Since the reform and opening up, China's fishery has adjusted its development focus and established a development policy focusing on aquaculture. The aquaculture industry has achieved rapid development, and the industrial layout has undergone significant changes. It has made remarkable achievements, accounting for about 80% of the world's aquaculture output. It has expanded to all parts of the country from coastal areas, Yangtze River, Pearl River basin and other traditional breeding areas. In recent years, China's aquatic product export volume and export volume have increased to varying degrees. In addition, the consumption of the domestic market is also increasing. Coastal areas, along the Yangtze River, the Pearl River Delta and the Yangtze River Delta are the main markets for aquatic products. In general, China is a large aquaculture country.

※ Current situation and demand

For a long time, most aquaculture producers and operators in China have been pursuing production and short-term economic benefits. The aquaculture density is too high, drug abuse, aquaculture diseases and industrial pollution are increasing year by year. In addition, the aquaculture pond is aging and the awareness of protecting the aquaculture environment is weak, so that the water environment is damaged to varying degrees. The quality and safety of aquatic products are not effectively guaranteed, and the sustainable development of aquaculture is seriously affected, How to improve the quality of aquaculture products, increase the economic benefits of operators, and achieve efficient, ecological and safe modern aquaculture industry has become a major problem to be solved in China.

The key parameters affecting the aquaculture environment include water temperature, light, dissolved oxygen, PH, ORP, residual chlorine, turbidity, conductivity, salinity, etc., but these key factors are invisible and hard to grasp accurately. The existing aquaculture management is guided by aquaculture experience, which is a universal aquaculture law. It is difficult to be accurate and reliable, and the output is difficult to be guaranteed. With the continuous development of aquaculture, market regulation is out of control, and competition is becoming increasingly fierce. It is imperative to master accurate and reliable aquaculture data, conduct scientific aquaculture, and improve production and quality.

※ System overview

The IOT aquaculture intelligent monitoring system developed and produced by Nobo Technologies has the following characteristics:

1. Parameters of water quality can be monitored in real time: water temperature, light, dissolved oxygen, PH, ORP, residual chlorine, ozone, turbidity, conductivity, salinity, ammonia ion, etc. Different monitoring parameters and collection schemes are provided according to different aquaculture environments such as freshwater, seawater and artificial seawater to ensure the accuracy and long-term stability of data. It can be integrated into multi parameter cabinet instrument.

2. Touch screen display operation, real-time display, operation and setting of multiple parameters. It is convenient for users to manage and view data in real time on site.

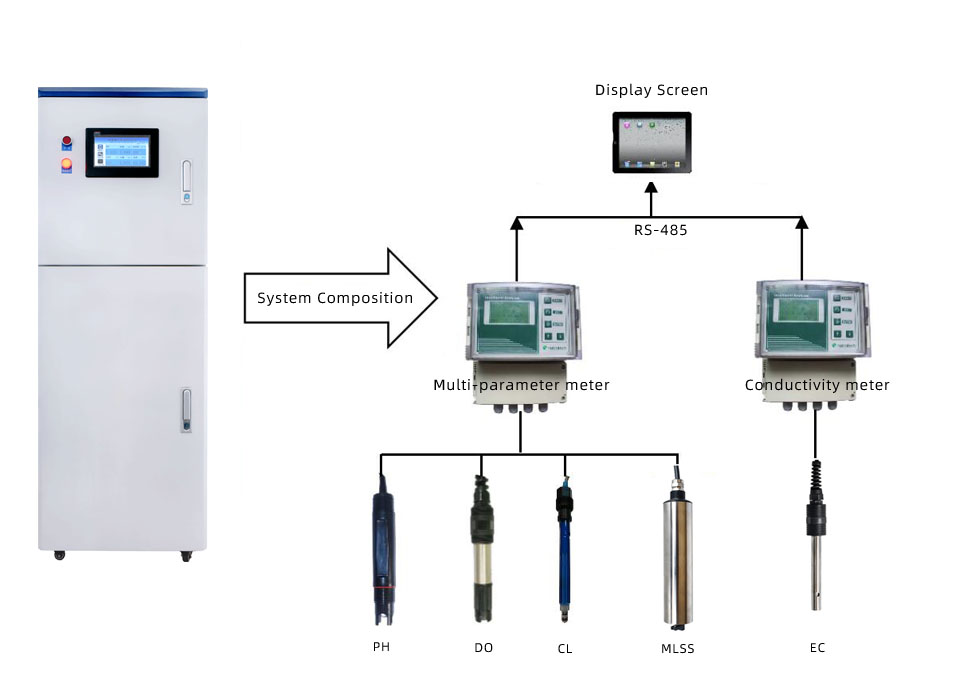

3. The system consists of sensor/electrode, transmitter (instrument), field touch screen, wireless module, duty host computer, user equipment control module, etc

4. It can automatically control the operation of relevant equipment, such as oxygenation equipment, PH buffer dosing equipment, disinfectant dosing equipment, etc. Realize unattended control of water quality parameters.

5. Data remote monitoring can monitor data in a short distance by wire, or alarm notification and data transmission can be conducted via the Internet through wireless modules such as wifi and gprs. Computers or mobile devices can remotely conduct real-time online monitoring of aquaculture water quality and check the operation status of relevant equipment through relevant software (such as host computer software system, mobile phone APP). It is convenient for users to receive alarms and store relevant data at the remote end.